Electronic design: from idea to product

Amarula Solutions offers a range of hardware development services to assist customers throughout the product development cycle. We can help with conceptualization, technical feasibility assessment, and development of initial product specifications. Our team is experienced in hardware design and PCB layout development, ranging from rapid prototype, to market products where performance, reliability, and manufacturability are prioritized.

We can provide block diagrams, schematics, 3D models and other technical documentation needed for the hardware design and procurement process from the supply chain, and manufacturing. We can produce and provide functional prototypes to test hardware functionality, evaluate product design, and identify any potential problems early in the development process.

In addition to prototype development, we provide small-scale production services (tens to hundreds) of electronic boards, including manufacturing, assembly, testing, and quality control.

Our team is well-versed in pre-compliance testing to ensure that products comply with regulatory requirements and identify any potential compliance issues prior to formal certification. We offer hardware testing services at accredited laboratories, including safety testing, EMC testing, environmental testing, and reliability testing, to ensure that the final product meets all necessary specifications and functions as intended.

Overall, our comprehensive hardware development services aim to provide clients with cost-effective, high-quality solutions that meet their unique requirements.

Circuit Design

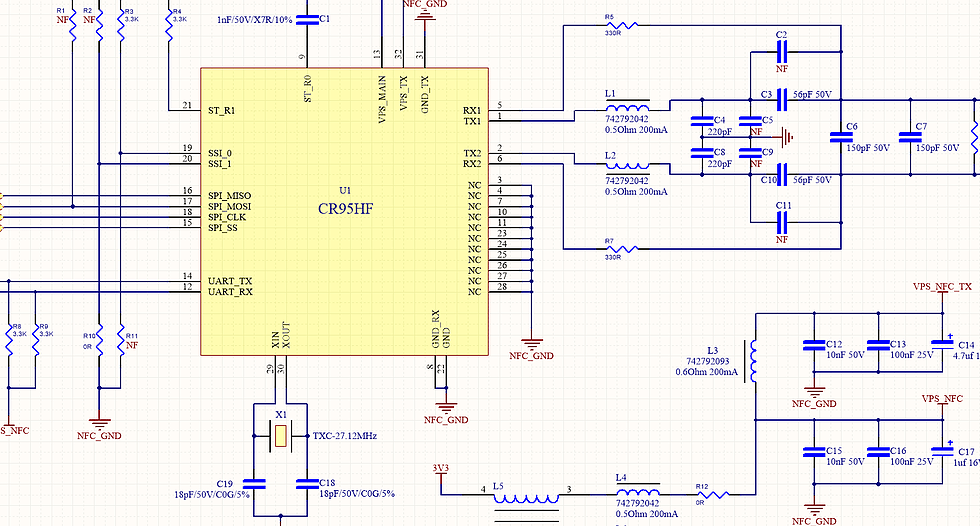

The heart of any electronic product design is circuit design. At Amarula Solutions, we use Altium Designer and Spice based simulation tools to capture your concept and convert it into a schematic diagram. We prioritize component cost, availability, EOL notices, and supplier quality when designing the schematic diagram.

The heart of any electronic product design is circuit design. At Amarula Solutions, we use Altium Designer and Spice based simulation tools to capture your concept and convert it into a schematic diagram. We prioritize component cost, availability, EOL notices, and supplier quality when designing the schematic diagram.

Additionally, we carry out Spice Simulation to test circuit performance before producing any hardware. Once the schematic design is complete, we provide a Bill of Materials (BOM) that enables you to obtain pricing structures from your end manufacturer.

When you need to test an idea, or produce a small number of boards while limiting investment, we also offer the ability to design rapid prototyping systems using the Raspberry PI / Pico, Arduino, STM32 Nucleus, ESP32, and other off the shelf platforms.

PCB

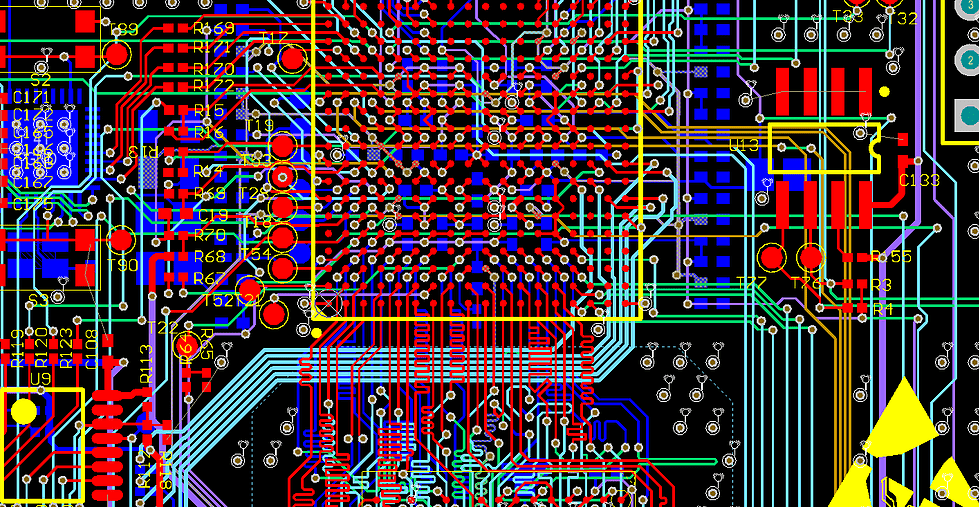

We specialize in designing PCBs to your exact specifications and producing prototypes. Our engineers understand that each PCB design requires varying levels of complexity. As a first step, we set up PCB DRC (Design Rule Checking) rules, which is a top priority during the initial stages of your PCB design. Correct use of DRC ensures that we can provide working designs with a high level of confidence. Your custom electronic product design begins to come to life.

We specialize in designing PCBs to your exact specifications and producing prototypes. Our engineers understand that each PCB design requires varying levels of complexity. As a first step, we set up PCB DRC (Design Rule Checking) rules, which is a top priority during the initial stages of your PCB design. Correct use of DRC ensures that we can provide working designs with a high level of confidence. Your custom electronic product design begins to come to life.

Upon completion, we provide a design package that includes:

- Schematic Design

- Bill of Materials

- Simulation Reports (where possible)

- PCB Layout Documents and Drawings

- Gerber & Drill Files

- Assembly Documents and Drawings

- Mechanical CAD 3D models and Drawings (if requested as part of the project)

CAD/CAE

Our team of engineers can take your product concept from stunning conceptual renders to full manufacturable designs. Once we have confirmed the PCB layout, we can export a 3D model of the printed circuit board with all the components fitted and test how it fits with either your provided enclosure CAD or design and develop the product enclosure for you upon request.

Our team of engineers can take your product concept from stunning conceptual renders to full manufacturable designs. Once we have confirmed the PCB layout, we can export a 3D model of the printed circuit board with all the components fitted and test how it fits with either your provided enclosure CAD or design and develop the product enclosure for you upon request.

Our engineering team will work closely with you to develop design concepts that meet your specifications. We will provide rendered images until you are completely satisfied with the look and feel of the product. Once the final design is approved, we will refine it further until it’s ready to be prototyped and manufactured.

We also offer 3D printing services to provide prototype parts for mechanical test purposes, ensuring that the final product meets all necessary specifications and functions as intended.

Our key points:

- Well suited Electronics laboratory.

- PCB development on Altium Designer.

- Mechanical development and 3D models on Solidworks.

- Custom enclosure design, 3D printing or off-the-shelf enclosures selection.

- Integration of electronics, PCB layout, and mechanical design.

- Development Platforms and System-on-Modules (SoM).

- Embedded Processor based Designs.

- Small-footprint hardware Designs.

- Power-optimized and Battery operated Designs.

- High-speed Digital Designs.

- Power Supply Design, Switch mode and Linear.

Custom Digital Design

Some projects require custom digital signal processing that might not be possible in off the shelf DSP processors. At the same time, doing a full ASIC run can take a long time, and is expensive.

Some projects require custom digital signal processing that might not be possible in off the shelf DSP processors. At the same time, doing a full ASIC run can take a long time, and is expensive.

FPGAs allow us to quickly develop a working solution that can be easily updated as requirements change during the development process. At Amarula Solutions, we have experience in digital circuit design using VHDL or Verilog for FPGAs from a variety of vendors. Our skilled team can also develop lowlevel device drivers that are essential for your applications to interact seamlessly with the hardware. With our FPGA solutions, we can help bring your innovative product ideas to life in a cost-effective and timely manner.

PCB Assembly

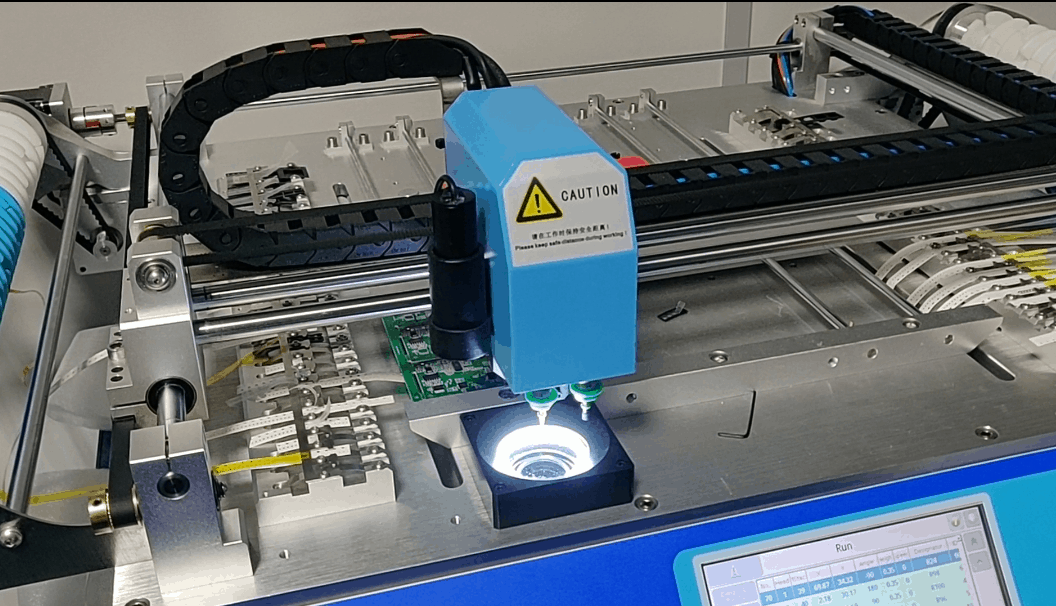

Amarula Solutions, through our partners, offers fast turnaround times for small-scale (tens to hundreds) electronic board production services at competitive costs.

Amarula Solutions, through our partners, offers fast turnaround times for small-scale (tens to hundreds) electronic board production services at competitive costs.

We can also provide functional testing and quality control service for boards.

Testing

Hardware Testing

Our team carries out thorough hardware testing to verify the functionality, performance, and reliability of your products. We perform functional testing to ensure that all features and components operate as intended. We have several procedures in place to perform performance and reliability tests; assessing the product’s capabilities under different scenarios and conditions.

Pre-compliance Assurance

We perform, in accredited laboratories, pre-compliance testing to ensure that your products meet regulatory requirements and identify any potential compliance issues before formal certification. This includes evaluating factors such as electromagnetic compatibility (EMC), electrical safety, and environmental standards.